2 Sided Exposure- Irregular Columns With Tracking Attachment

Recommended Panel Configuration & Measuring

If you have irregularly-shaped columns, you have one choice, an Inside Hang, where panels take a path INSIDE your columns.

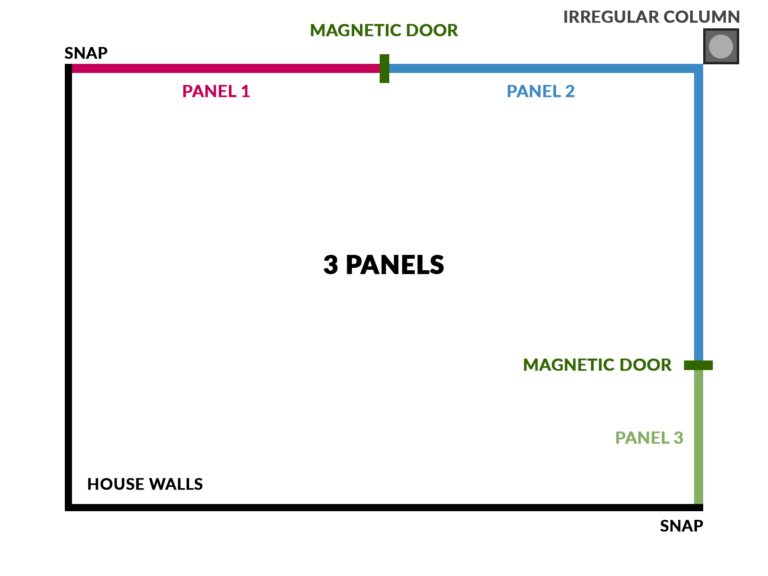

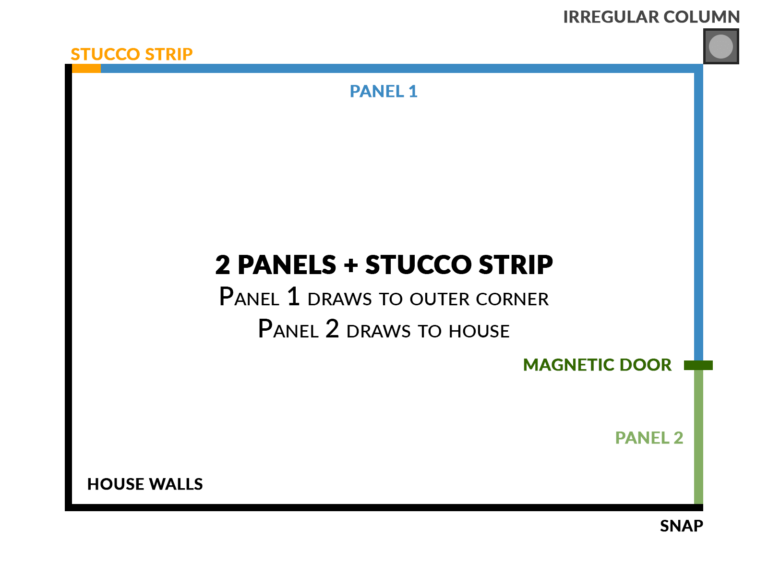

Projects with Irregular-shaped columns are generally 3 panel configurations for ease of use and natural looking swags. Because we cannot fasten a panel directly to the irregularly-shaped corner column, the second panel will straddle the corner column.

Measurement Tips

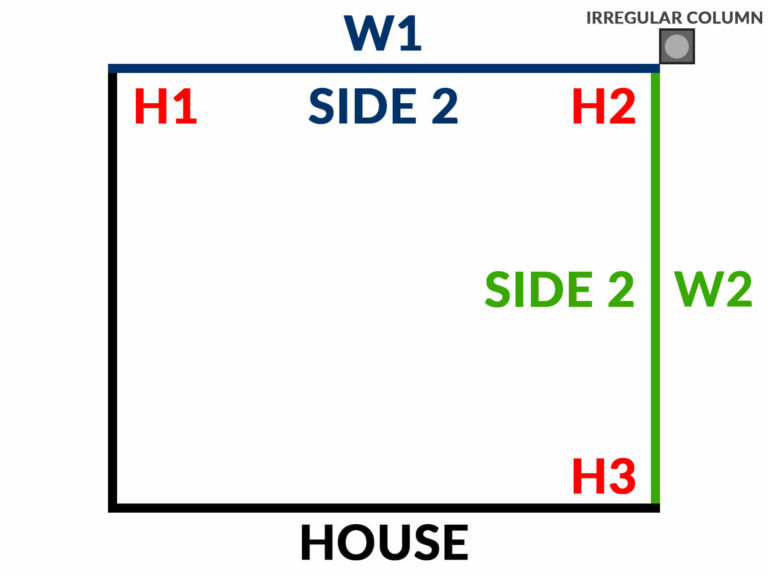

- Measure the exposed widths of both sides ALONG the path your tracking will take WITHOUT ANY OVERLAP (which we will adjust for momentarily).

- Measure heights at all 3 corners from underside of track mounting surface to floor. The 3 heights could be different and you cannot assume all heights are the same.

- If for some reason you don’t have a good under-mounting surface, remember you can make one by side-mounting a 2″ x 2″ wood strip, then under-mounting track to the wood strip.

- We divide your project into 3 individual panels where the second panel will straddle the outer corner.

- 2 Panel breaks with magnetic doorways are wherever you like on each of the 2 sides.

- IMPORTANT: Sum width of all sides = Sum of all panel widths.

The configuration diagrams below demonstrate two examples from a top view using marine snaps, magnetic doorways, and stucco strips. Watch the video to get an overview on how to measure and some ideas for your panel configuration.

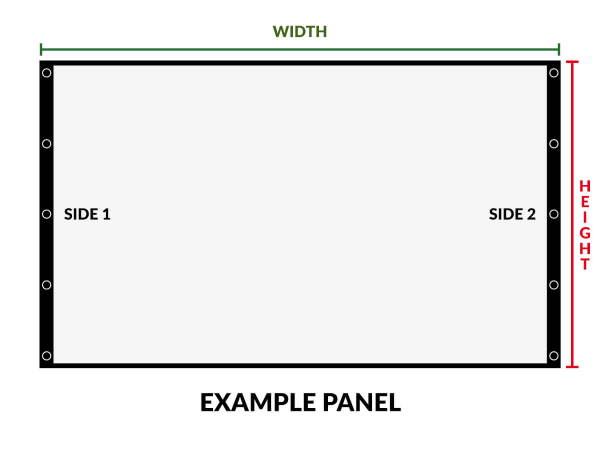

Panel Adjustments (Or Use Calculator Below)

WIDTH ADJUSTMENTS (or use calculator below)

- Automatically add 2-inches per panel regardless of width, then

- Add another 1-inch per panel for EACH edge that will snap to some surface

- Subtract 1-in for EACH edge connecting a Stucco Strip, and ignore width of stucco strip

- For Tracking Attachment: Add another 1-in per 10ft of panel width for relaxed fit

HEIGHT ADJUSTMENTS

- NO height adjustments necessary for tracking. The 1-inch drop in the track will automatically give you a 1-inch overlap with the floor.

- Measuring is done from the bottom of the track mounting surface to the floor.

Simple Panel Adjustment Calculator (if all heights are the same)

Use this calculator by entering the 5 pieces of information required to adjust your panels. Repeat for each panel larger than a stucco strip.

NOTE: If the difference between all 4 heights is less than 1.5-inches, just use the tallest of the 4 heights. If the heights differs more than 1.5-inches, call in your order because we will need to taper the slope.